|

|

|

MARUWA's Printed

Circuit Boards (PCB) Meet All Exacting

Needs in High Technology Areas

Printed circuit boards (PCB) play an unquestionably

important role in the development of electronics and

electronic systems and equipment. MARUWA supplies a

great diversity of high-quality PCB reflecting its own,

highly advanced manufacturing know-how and application

technologies and meeting all kinds of industrial and

consumer requirements, thus contributing greatly to

further sophistication and functional improvement of

electronic systems and equipment.

|

|

Flexible

Printed Circuit Boards (FPC)

The

ever growing user demands for upgraded performance,

higher packaging density and downsizing of electronic

equipment have inevitably called for an advanced wiring

design and pattern providing greater economy of

packaging space. The flexible printed circuit board is

best suited to the realization of such advanced wiring

design and pattern. It produces the highest conceivable

effect in the design, development, manufacture and

quality control of any and all kinds of electronic

equipment, and thereby realizes a substantial reduction

in total production cost. In addition, FPC offers the

possibility of flexible utilization of various novel

ideas in the process form wiring design to the mounting

of semiconductor devices. It can thus be positioned as a

ideal printed circuit board in the new era of

information. |

|

|

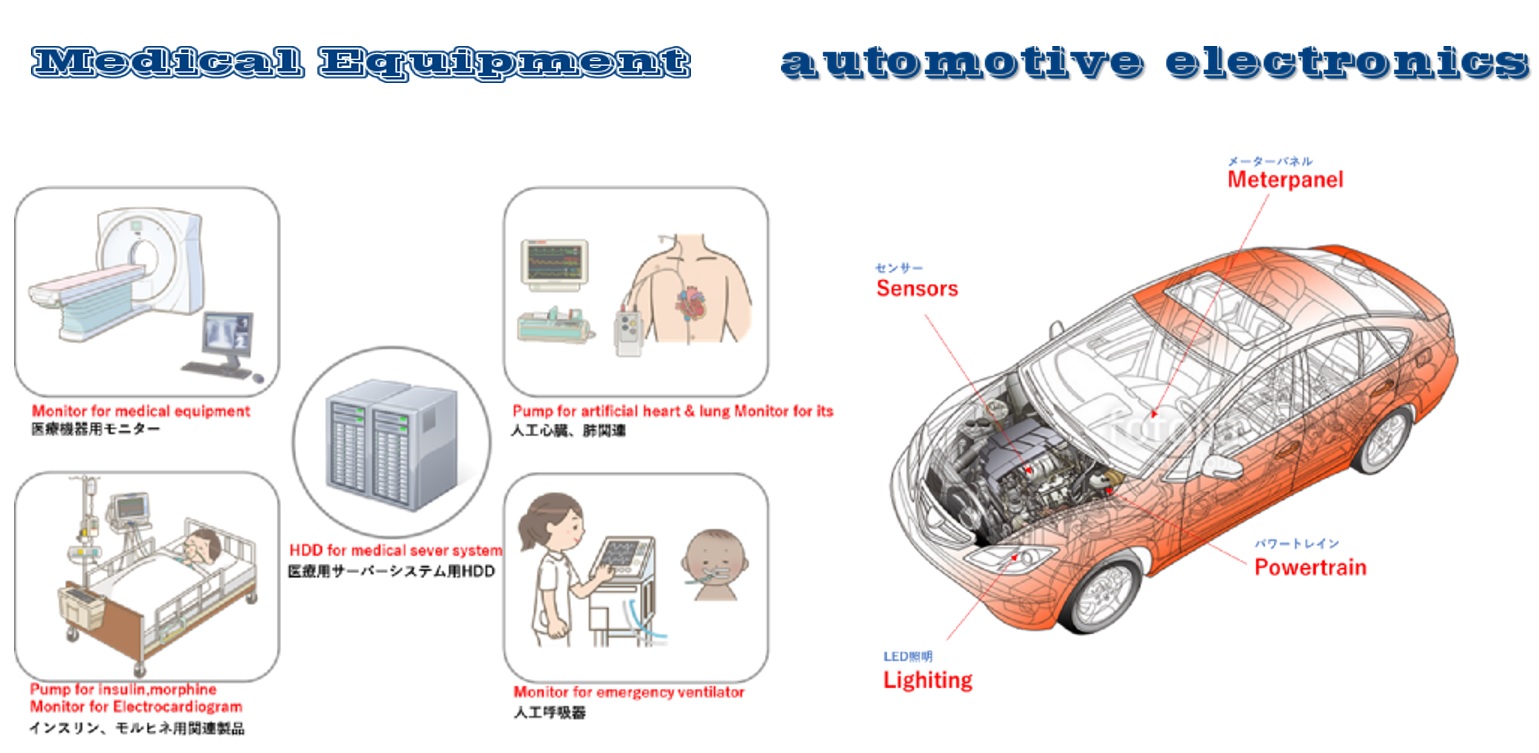

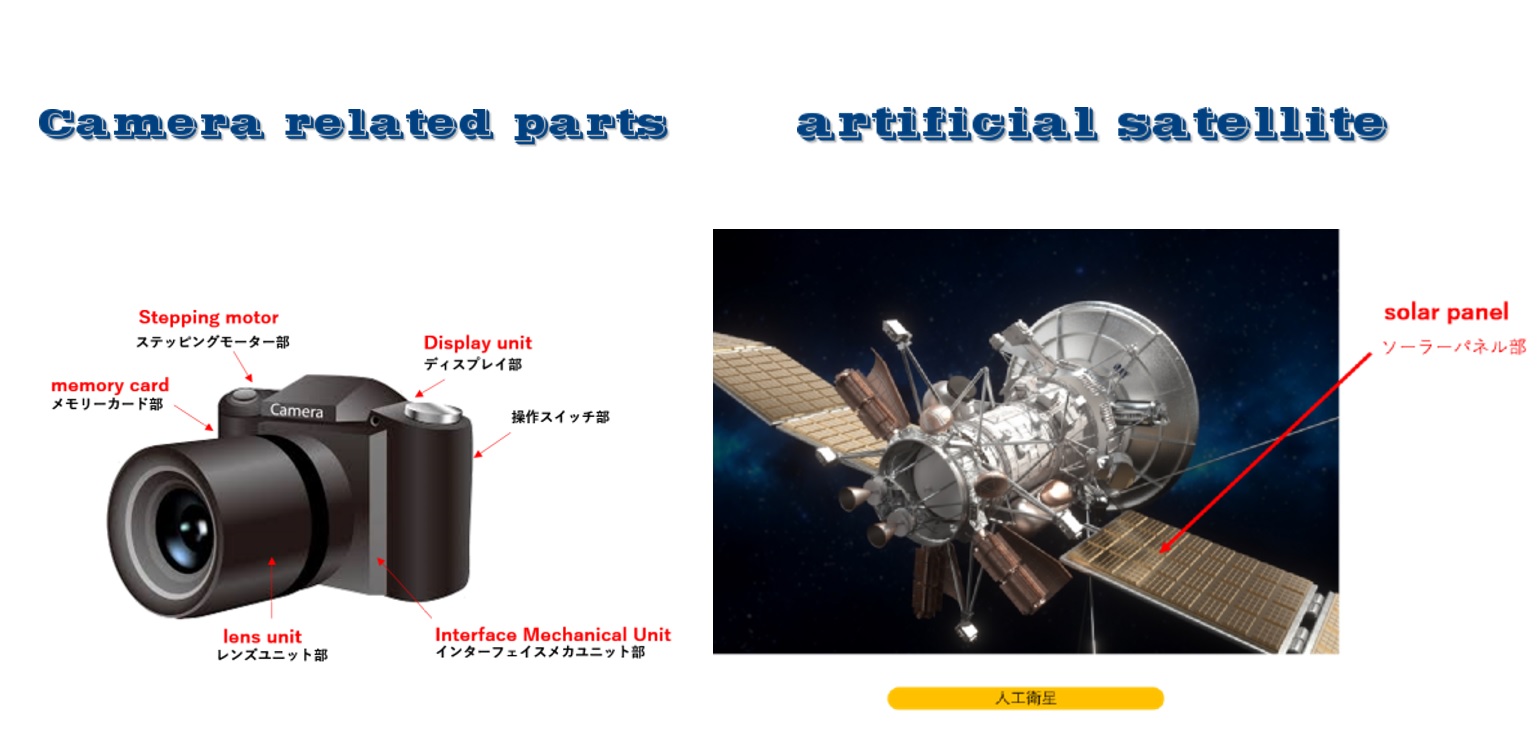

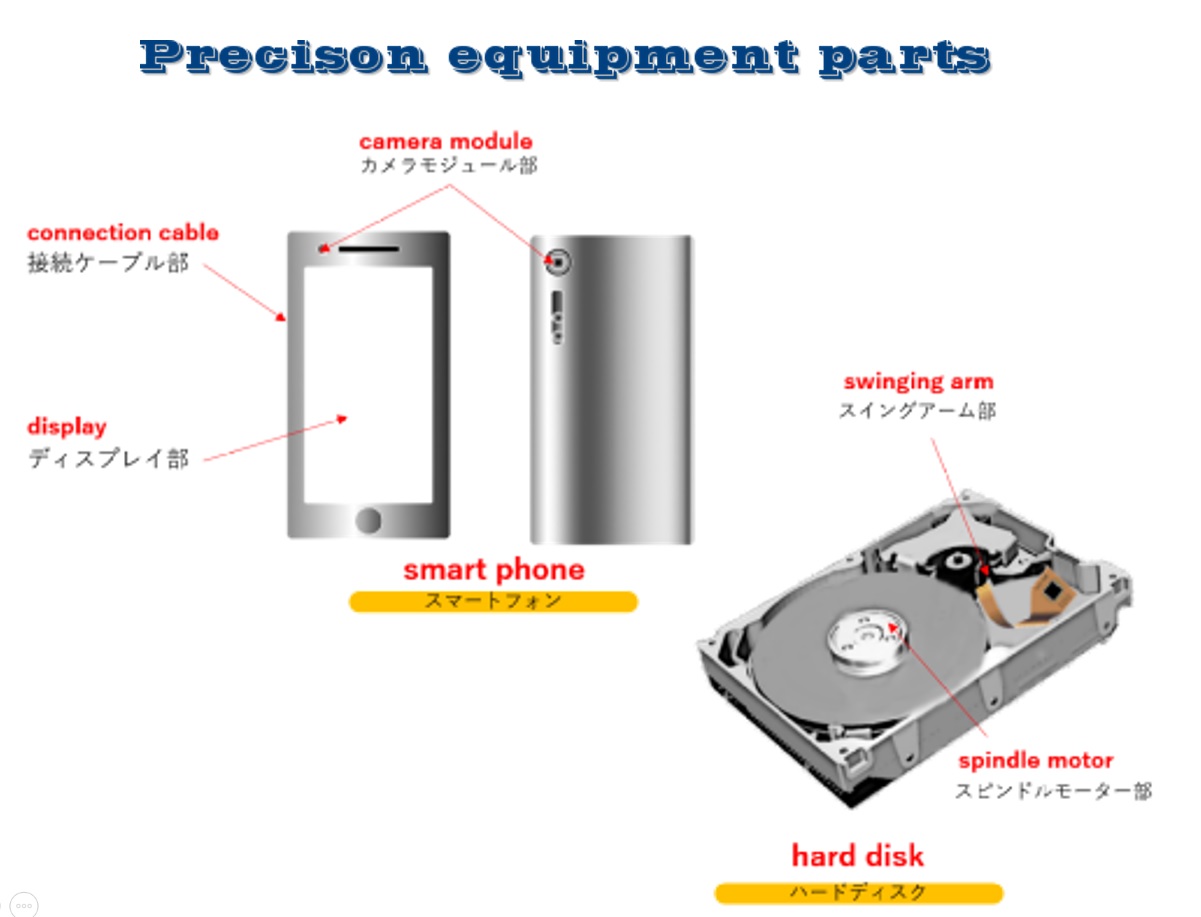

Application of FPC at Denshi Maruwa

Major Products

|

|

|

Quality Policy

DENSHI MARUWA INDUSTRIES (M) SDN BHD (herein after DMI),

as a component manufacturer of highly reliable and

high-quality Flexible Printed Circuit Board (FPC) is

devoted to implement and maintain an excellent Quality

Management System based on ISO9001:2015 standard with

our strong commitment to continues improvement towards

customer satisfaction through;

|

1. |

To establish a quality system that enhances the

production of world’s highest quality at

competitive price.

|

|

2. |

To continue to improve our quality system in

order to fulfill the requirements in all aspects

effectively.

|

|

3. |

To review the means of achieving quality

objectives consistently.

|

|

4. |

To ensure all employees understood the quality

policies and targets. |

Environmental Policy

DENSHI MARUWA

INDUSTRIES (M) SDN. BHD. (hereafter DMI), as a component

manufacturer of highly reliable and high-quality

Flexible Printed Board (FPC) is devoted to implement and

maintain an excellent Environmental Management System

based on ISO 14001 standard with our strong commitment

to continuous improvement through:

|

1. |

DMI is

committed to comply with all applicable

environmental laws and legislations and uphold

customer’s requirements, which relate to our

environmental aspect.

|

|

2. |

DMI will

implement and improve continuously to save

natural resources and hence will prevent of

pollution and protect the environment from DMI

manufacturing activities;

|

i) |

To

reduce the consumption of electricity

and water through cost reduction

program.

|

|

ii) |

To

reduce and control the generation of

waste in production process through

minimization of product defects programs

and recycling.

|

|

iii) |

To

control and reduce the usage of chemical

materials.

|

|

|

3. |

DMI will set

and review the environmental objectives and

targets periodically and improve environmental

performance.

|

|

4. |

DMI will

communicate, educate and train all employees and

all persons working on behalf of DMI the

documented policy in order to create the

awareness and responsibilities as required in

Environment, Quality, and Safety and Health

aspect.

|

|

5. |

This policy is

available to public upon request.

|

Occupational Safety & Health Policy

|

1. |

DENSHI MARUWA INDUSTRIES

(M) SDN. BHD. (DMI) REGARDS THE PROMOTION OF

OCCUPATIONAL SAFETY AND HEALTH MEASURE AS A

MUTUAL OBJECTIVE OF MANAGEMENT AND EMPLOYEES AT

ALL LEVELS. IF THERE IS A CONFLICT BETWEEN

PRODUCTION AND SAFETY, SAFETY CONSIDERATION WILL

TAKE PRIORITY.

|

|

2. |

IT IS

THEREFORE DMI’S POLICY TO DO ALL THAT IS

REASONABLY PRACTICABLE TO PREVENT INJURY, DAMAGE

TO PROPERTY AND ENVIRONMENT AND TO PROTECT every

one FROM FORESEEABLE OCCUPATIONAL HAZARDS.

|

|

3. |

it is the management’s responsibility therefore

to :-

|

3.1 |

provide and maintain safe and healthy

working conditions. Taking into account

of any statutory requirement

and

relevant national and international

standards and codes of practice.

|

|

3.2 |

provide training and instruction to

enable employees to perform their work

safely and efficiently.

|

|

3.3 |

make available all necessary safety

devices and protective equipment and to

supervise their use.

|

|

3.4 |

Maintain a constant and continuous

interest in health and safety matters

applicable to the company’s activities

in part particular, by involving

employees or their representative

wherever possible.

|

|

|

4. |

employees have a duty and responsibility to

cooperate fully in the operation of this policy

by :-

|

4.1 |

working safely and efficiently.

|

|

4.2 |

using the protective equipment provided

and meeting statutory obligations.

|

|

4.3 |

reporting accidents dangerous

occurrences that had led or may lead to

injury or damage to property and

environment.

|

|

4.4 |

adhering to company rules and procedures

for securing a safe system and place to

work.

|

|

4.5 |

assisting in the investigation of

accidents or dangerous occurrences with

the objective of introducing measures to

prevent a recurrence. Time factor should

also be of great importance in

investigation – the shortest possible as

well as accurate findings. |

|

“THE SAFE WAY IS THE BEST WAY”

|

Next >> FPC

Process Flow >> Die Set Process Flow |